When companies have issues such as "We are looking to reduce the cost of treating industrial waste at our plant" or "The cost of solvents is rising", then KOBEX can support these companies by introducing various product solutions.

Features

Features1

It is possible to recover (recycle) Class 1 and Class 2-type of petroleum such as thinner, toluene, acetone, MEK, and ethyl acetate. Also alcohols such as methanol, ethanol, IPA, and fluorocarbon- and chlorine-based solvents.

Features2

Our proprietary technology enables us to regenerate the solvent under vacuum conditions, lowering the boiling point of the solvent and reducing electricity and energy costs.

Benefits of Installing Equipment for Solvent Regeneration

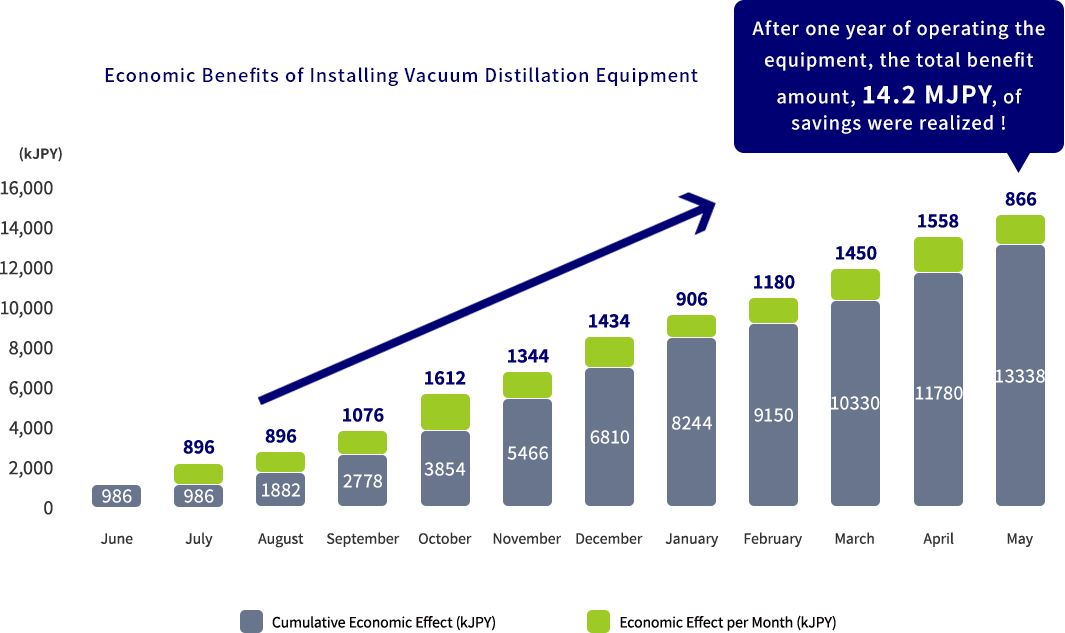

For example, if you produce an average of 40 drums of ethyl acetate waste liquid per month, you can expect to reduce costs by about 1.2 million yen per month, or more than 14 million yen per year. For details, see the table below. In addition, instead of disposing of the discharged residue, it is instead possible to sell the recycled waste liquid to a recycling company.

- Equipment Introduction Benefit Data

- This is the benefit data of a user that installed CA-802. By implementing in-house recycling of an average of 40 drums of waste solvent per month, compared to the previous year, the company was able to reduce costs by 14.2 MJPY per year. This by reducing the amount of new cleaning solvent and cost of waste !

Product Introduction

-

Compact Solvent Recovery Equipment

CA-100 Series

If your amount of waste solvent discharged is less than 2 ton per month, click here

more -

Vacuum Distillation Continuous Recovery Equipment

CA-800 Series Invention Award

Invention Award

Winner

If your amount of waste solvent discharged is 2 ton or more per month, click here

more

Contact Us

-

For those who would like to receive product

catalogs, specifications and instruction manuals -

For those who would like to hear more about our

products and quotations -

Demonstration units can be rented