KOBEX's Strengths

Comprehensive Solutions for Organic Solvent IssuesSuggestion

Comprehensive Solutions for Organic Solvent IssuesSuggestion

We can propose solutions with 3G, which goes one step beyond the 3R (Reduce, Reuse, Recycle).

QuantumQuantum of Experience

QuestQuest of the Challenge

QualityQuality of Safety

Custom DesignOrder made

Custom DesignOrder made

We can design and manufacture custom made equipment in accordance with the facility standards and explosion proof specifications of each customer's plant, both for domestic and overseas use, in addition to the required specification of each customer.

Unique Technological CapabilitiesTechnology

Unique Technological CapabilitiesTechnology

Leveraging our unique technological capabilities, we have an extensive track record in addressing challenging issues such as SDGs, zero emissions, carbon neutrality, and ISO14001.

Pursuit of Safety

We are always mindful of safety during operation of the equipment, and have selected equipment with no ignition sources within the system, as well as explosion-proof specifications. In addition, we have invented a unique heat pipe structure for the heat source and have obtained a patent for a vacuum distillation continuous recovery method, thereby continuing our pursuit of safety.

Product Introduction

There are no complicated operation processes and all of them are easy to perform.

-

What is Solvent Regeneration (recovery) ?

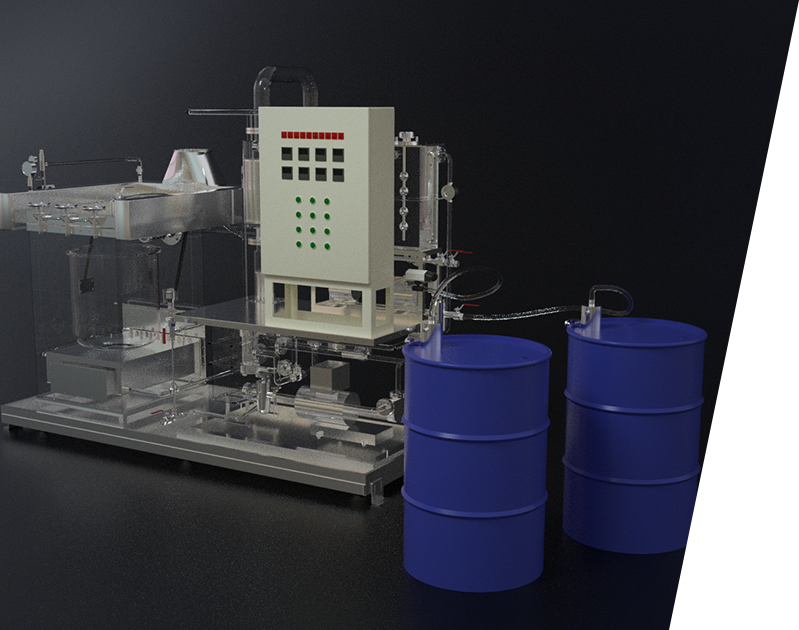

CA-100 Series / CA-800 Series

Contributes to the recycling of solvents at various plants

more -

Explosion-proof Automatic Cleaning Equipment

CA-400 Series

Cleans the ink and paint filling tanks in the plant and recycles the solvents after cleaning

more -

Deodorization (VOC) Treatment Equipment

CA-700 Series

Eliminates solvent odors based on technology cultivated in solvent regeneration

more

Benefits of Installing the EquipmentMerit

-

What is Solvent Regeneration (recovery) ?

CA-100 Series / CA-800 Series

80% of the solvent is recycled, which means reduced purchasing and disposal costs

-

Explosion-proof Automatic Cleaning Equipment CA-400 Series

Reduced labor costs by 50% through machine cleaning

-

Deodorization (VOC) Treatment Equipment

CA-700 Series

Deodorizing (VOC) treatment equipment improves the plant environment for a comfortable workplace

Implementation Result

We have a proven track record of delivering to a wide range of industries and business types, both domestic and overseas

- Delivery Records until Year 2022

- 4000

Units

- Delivery Lead Time

- From

30Days

Business CategoriesIndustry

- Automotive-related (Painting and Machining)

- Paints and Inks (Chemical plants)

- Gravure / Flexographic Printing (Processing plants)

- High-performance Materials and Films (Smartphones/EVs)

- Rubber, Glues / Adhesive Materials (Material manufacturers)

- Semiconductor-related (Dehydration process)

- Medical Equipment and Pharmaceuticals

- Various Development and Research Laboratories

※In addition to the industries listed above, please contact us if you have any issues related to solvent processing and handling at your plant, etc.

Case StudiesExample

-

Mitsubishi Chemical Infratec Co., Ltd

Left: Norikazu Aoyama, General Manager of Ueda Plant

Right: Masayuki Kobayashi,

General Manager of Coating Section, Manufacturing DepartmentSignificant reduction in thinner purchase and disposal costs ! A recycling rate of up to 90% contributes to cost reduction at the plant

more -

Tokyo Ohka Kogyo Co., Ltd

Promoting recycling by converting waste into valuable resources

more

Contact Us

-

For those who would like to receive product catalogs,

specifications and instruction manuals -

For those who would like to hear more about our

products and quotations -

Demonstration units can be rented

Process Flow until DeliveryFlow

- Meeting Arrangement and Sample Test

- Determination of Equipment Type and Specification

- Purchase Ordering (Products are Manufactured to Order)

- Pre-delivery, Commissioning Adjustments

- On-Site Commissioning Adjustments (Separate consultation may be required depending on the installation location)

- Delivery Completed ~ Equipment in Operation

- After Sales Support・Operation

NoticeNews

- 2025年05月19日 Press Release KOBEX Co., Ltd. to exhibit at the “MEX Kanazawa 2025”

- 2025年05月19日 Press Release KOBEX to exhibit actual machine “CA-103V-C” at INTERMACH 2025

- 2025年05月15日 Press Release Notice of FY2025 Kobe Small and Medium-sized Enterprise SBT Certification Subsidy Grant

- 2025年05月06日 Press Release KOBEX Co., Ltd. obtains SBT (Science Based Targets) Certification

- 2025年03月12日 Press Release We exhibited at the “Next Generation Battery Technology Exhibition”

Contact Us

-

For those who would like to receive product

catalogs, specifications and instruction manuals -

For those who would like to hear more about our

products and quotations -

Demonstration units can be rented