It is suitable for applications where the amount of waste solvent discharged is less than 2 ton per month.

You can see how to use the product by watching the video

Atmospheric Distillation Recovery Equipment

CLEAN-ACE101

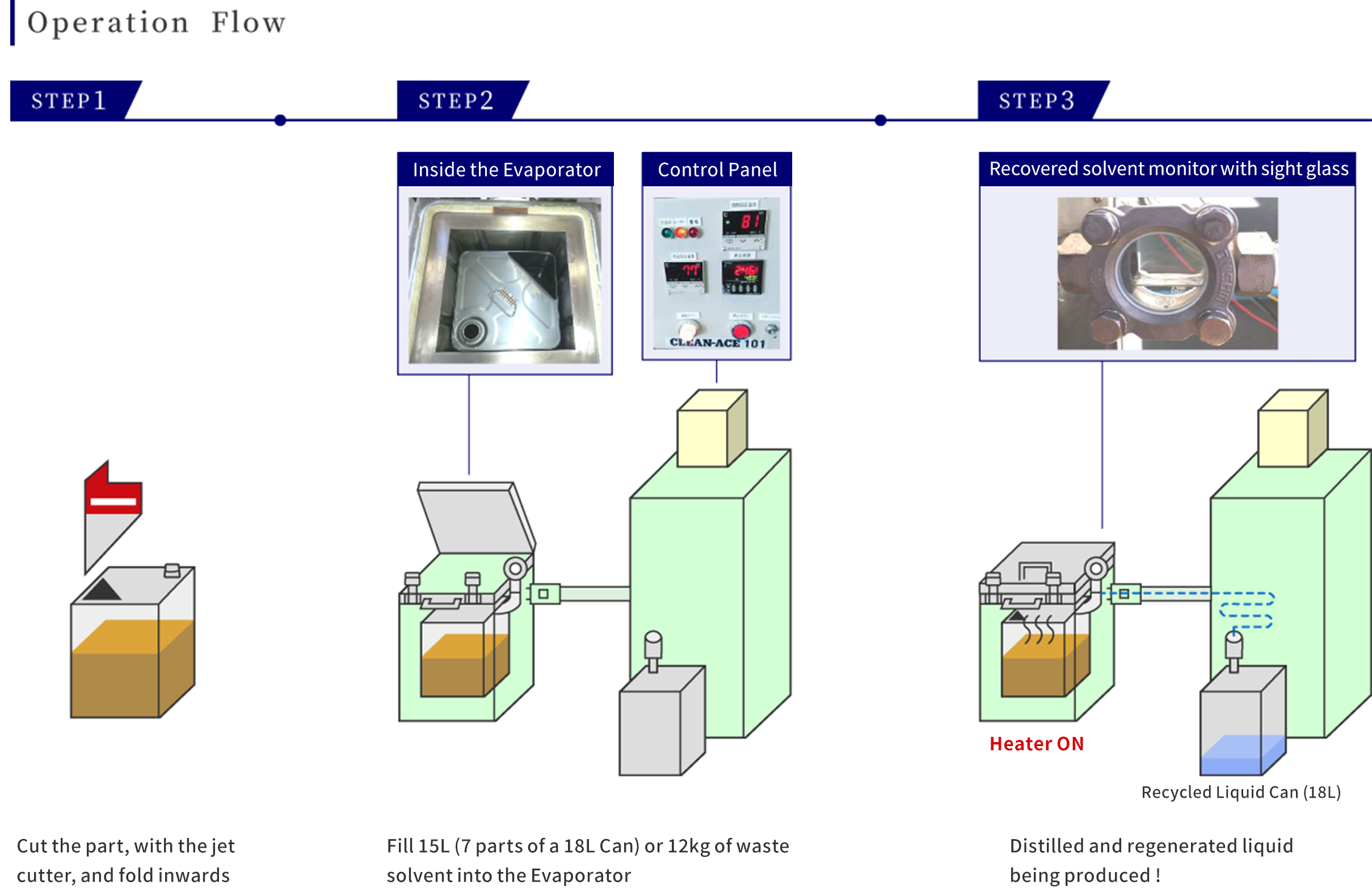

For the atmospheric pressure type, all that is necessary is to place the 18L Can containing the waste liquid type into the evaporator, set the operating temperature and time, and press the operation button. After a period of time, the distilled and regenerated liquid will be produced.

CA-101-AWatch it in the virtual plant

CA-101-2DCWatch it in the virtual plant

Compact Solvent Recovery Equipment

CA-100 Series (Atmospheric Pressure)

CA-101 Line Up

| Specification | Model | ||

|---|---|---|---|

| CA-101-A | CA-101-2DC | ||

| Distillation Method | Atmospheric Distillation (batch type) | ||

| Processing Method | 18L Can processing OR heat-resistant Bag | ||

| Applicable Solvent | Petroleum Class 1 & Class 2 | Petroleum Class 1 & Class 2 | |

| Equipment Specification | Safe location type | Completely Explosion proof | |

| Processing Capacity | 15-18L/batch (3-4hrs) | 30-36L/batch (3-4hrs) | |

| Power Supply | 200V Single-phase 2.0kW | 200V Single-phase 4.0kW | |

| Heating Method | Heat pipe | Heat pipe | |

| Control Panel | Pressurized explosion proof | Pressurized explosion proof | |

| Chiller Unit | ※ Optional | ||

Compact Continuous Solvent Regeneration Device

CLEAN-ACE101-2DC Auto

ACE101-2DC Auto

This unit can automatically supply/feed liquid from the waste solvent drum to the recovered liquid drum. All that is necessary is to set a lancer nozzle on each drum for handling. Temperature control and distillation recovery during operation is performed automatically by the unit. In addition, an alarm will sound when the inlet of the contaminated liquid drum is low on solvent, or when the collected liquid drum is full. The alarm will also be displayed on the collective error indicator. All interlock measures and equipment are explosion-proof, so it can be operated safely in an explosion-proof location.

| Distillation Method | Applicable Solvent | Equipment Specification | Processing Capacity | Power Supply | Heating Method | Control Panel | Cooling Water |

|---|---|---|---|---|---|---|---|

| Atmospheric Distillation (continuous type) |

Petroleum Class 1 & Class 2 | Completely Explosion proof |

9~12L/Hr | 200V Single-phase 5.0kW | Heat pipe | Pressurized explosion proof |

0.2MPa 15L/min |

Vacuum Distillation Recovery Device

CLEAN-ACE-103V

The vacuum method is suitable for the recovery of hydrocarbon-based solvents with a boiling point of 150℃ or higher. Since it is a low-temperature process, it is possible to suppress thermal decomposition during high-temperature treatment in atmospheric distillation and deterioration of the quality of the recovered liquid due to oxidative degradation. In addition, by eliminating the third of the three elements of explosion ((1) Combustible materials, (2) Ignition sources, (3) Oxygen), it is possible to increase the safety during operation.

CA-103V-AWatch it in the virtual plant

CA-103V-C

| Specification | Model | |

|---|---|---|

| CA-103V-A | CA-103V-C | |

| Distillation Method | Vacuum Distillation (batch type) | |

| Processing Method | Direct feeding OR heat-resistant Bag | |

| Applicable Solvent | Petroleum Class 1 & Class 2 | Petroleum Class 1 & Class 2 |

| Equipment Specification | Safe location type | Completely Explosion proof |

| Processing Capacity | 15-18L/batch (~3hrs) | 15-18L/batch (~3hrs) |

| Power Supply | 200V 3-phase 3.0kW | 200V 3-phase 3.0kW |

| Heating Method | Heat pipe | Heat pipe |

| Control Panel | Pressurized explosion proof | Pressurized explosion proof |

| Chiller Unit | ※Optional - Cooling water of 0.2MPs and 15L/min is required | |

Details of Other Products

Contact Us

-

For those who would like to receive product

catalogs, specifications and instruction manuals -

For those who would like to hear more about our

products and quotations -

Demonstration units can be rented